History

In the 1800’s there were at least three brickyards near Chapel Road, Ramsey Heights, because the Oxford Clay used for making bricks is only just below the surface here. The 1874 OS map shows two brickyards on the north bank of the Catchwater drain and one on the south, the present site of the Countryside Centre.

The brickyards were set up here because as well as the clay being available, peat was dug locally in Woodwalton Fen and Lotting Fen and could be used for fuelling the brick kilns; also the fen waterways made it easy to transport the finished bricks and tiles out to the customers.

In 1854 the brickworks passed into the ownership of George Harris and Beasley Summers and remained in the Summers family for four generations – Beasley, John, Fred and Fred junior until the yard closed around 1920. At the end of the 19th century, eight men were employed in the summer and five men in the winter. Extra labour was needed to load the kiln and make the bricks, tiles and pipes, some of this work was done by women and children.

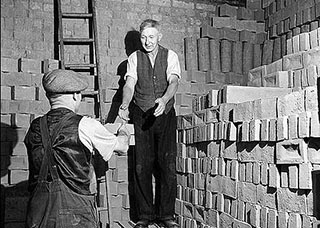

Photo : The Great Fen - Ramsey Heights Brickworks

Production at the brickyard

Buildings at the brickyard: There was a kiln building and hopper for the fuel, sheds for making bricks and tiles and a 100-foot long drying shed, cottages for the workers, some houses and a bigger house for the Summers family. A Methodist chapel was built in the corner of the site in 1871 for the workforce and a schoolroom added later, which still survives as a private house. A pub, The Prince of Wales also existed and was owned by the Summers family, wages were paid here and no doubt much spent here too.

Making the bricks and tiles: Clay or gault was dug in the winter from October to April and bricks were made from April to October. Some of the pits dug to extract clay can still be seen at the Countryside Centre alongside the Catchwater drain. When the clay was first dug it was left for the weather to break it down, it was turned twice and tempered to try and get an even consistency. A pug mill was then used to mix the clay with some sand and water, giving a smooth pasty mix.

For bricks, the clay mix was put in wooden moulds larger than was needed as the clay shrank during drying and firing. The wet bricks were removed from the mould and placed on a rack in a drying shed. When they were half dried they were placed in a herring-bone fashion to allow the air to pass between them. The drying took 3-6 weeks before they were ready to be fired in the kiln.

Tiles were made using the same pasty clay mix, using a crank-handled machine that squeezed the clay through a ‘die’ onto a long table made up of little rollers. A wire cutter came over the table and cut the tiles to length. The tiles were placed on a tray and the corners cut off. The wet tiles were placed on a rack in in the drying shed on slatted shelves 20 foot long. Tiles were stacked up to 12 foot high without touching each other.

Loading the kiln: A kiln-man was in charge of the kiln helped by two labourers, who carried bricks to him from a drying stack. The floor of the kiln had four trenches; arches were built with ‘green’ bricks over the trenches. Where the arches met, this was the first level. Planks were laid over the first level to enable the men to move about and then the second level was built, in a herringbone pattern. The first level had to be brick, but tiles were more profitable so as many tiles as possible were put into the second and third levels. Drainage pipes were also fired and these would be placed upright at one end of the kiln, with smaller pipes placed inside larger ones to save space. It took four days to fill the kiln, then the top and entrance were closed using old bricks. A kiln load could hold about 40,000 bricks.

Firing the bricks: The kiln-man made a small fire in each trench on the hopper side of the kiln and this would be increased until the fire reached right across the kiln. This process (tanning) continued for about nine days until all the moisture was removed from the clay. Iron furnace doors were put over the hopper end of the trenches and more fuel was added to make as much heat as possible. After about three days the top of the kiln would be red hot where the fire had burned through and wet clay was put on top. Adding wet clay on top of the hot kiln was a difficult and dangerous job as the heat and fumes could be overpowering. The kiln had to cool before bricks were removed, then another three days were needed for them to cool completely.

Delivering the bricks to the customers: Barges or lighters were used to take the finished bricks away to customers, each brickyard having its own watermen. The ‘Y’ shaped pond nearest the present-day Classroom building was the old loading dock or harbour where boats could turn round and load up. The dock led out into the Catchwater drain, which was wider and deeper than it is now, and had a towpath for horses. The Catchwater led into the Raveley drain and the boatmen could then navigate round to St Mary’s bridge (Hitson’s bridge) and so on into Ramsey or the wider Fen waterways. On the return journey the lighters brought in sand and (later on) coal for firing the kiln.

Photo: The Great Fen - Delivering Bricks Ramsey Heights

From brickyard to education centre

After the brickyard closed, a few families continued to live in cottages on the site. The footings of some cottages can still be seen and the fruit trees planted in their gardens still bear fruit every year. The Harlock family was the last to live here, raising cattle on some of the site including land over the other side of the Catchwater. Part of the land was used by the local council, Ramsey UDC who dumped household waste on what is now the main car park and ‘night soil’ sewage on other areas, before modern sewage systems were in use. When the workings stopped the clay pits soon filled with water and became an area of great importance to local wildlife. Trees, brambles and nettles soon took over.

The Wildlife Trust was alerted to the possibilities of the site by a local farmer; the Trust leased the site from the local Council in 1971 and then bought it in 1976. At that time there were two derelict buildings, a cow shed and the kiln building. Everything was overgrown with nettles, brambles and trees and there were water-filled pits left over from the clay diggings. Major restoration was carried out on the kiln from 1976-79, mostly carried out by volunteers, which produced a useful site facility for both adults and children but only really suitable for use in the summertime.

Another phase of restoration was carried out in the 1990’s, the sites of the Mere and the dock were cleared and improved. In 2007-8, as part of the Great Fen project, funding was made available for a second restoration which resulted in a building with modern facilities that could be used year-round by schools, adults, special interest and family groups.

Photo credit - The Great Fen - Ramsey Heights Countryside Centre